If you examine a label of a car engine, you’ll easily spot that it features many components. No one is of little importance, else manufacturers won’t add them. It’s easy to say every system in a car depends on the engine to work without issues. However, most of these components are as dependent on an actuator device as they are on the engine. Read on to find out what precisely an actuator does in car engines in this comprehensive guide.

Understanding Actuators in Car Engines

An actuator generates mechanical energy from electric, hydraulic, or pneumatic power sources. Then, the engine uses the new energy to operate different systems, ensuring top-notch performance. For the most part, however, actuators help foster fuel efficiency and reduce emissions.

But the actuator doesn’t work on its own. It first receives a signal from a control unit, which can be a sensor or energy source. The latter is most common since most cars come with electric actuators that use a motor.

It’s the control unit that tells the actuator what to do and when to do it via the signal. Usually, the signal is low-voltage. But, the current driving the device to perform is high-voltage, depending on the load.

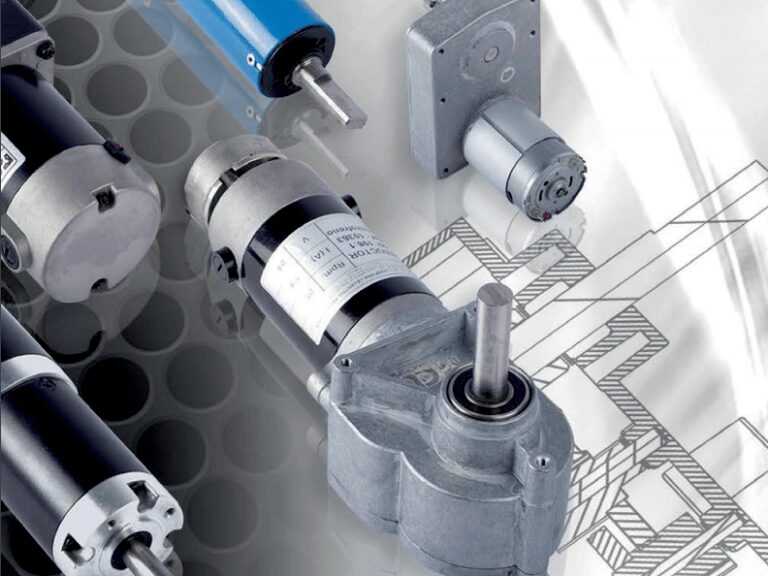

When generating power, the actuator will either follow a straight or round patch. If it goes straight, it’s a linear device; if round, it’s a rotary actuator. Modern cars feature more linear actuators than rotary ones. Nevertheless, it depends on the engine type, and you can check here to better understand them.

Functions of Actuators in Car Engines

The role actuators play in car engines cannot be under-emphasized. In that regard, here are some critical functions the devices handle:

Throttle Control

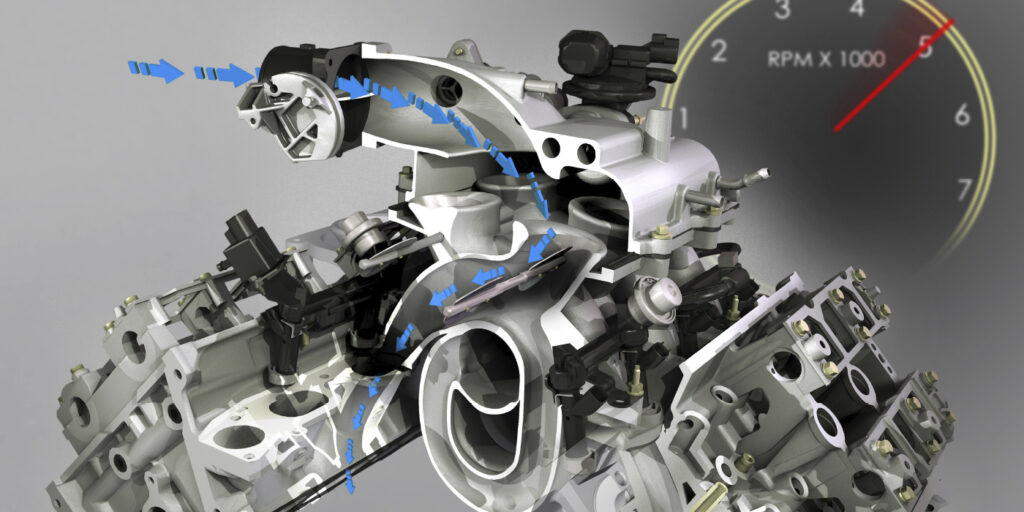

The throttle handles the air and fuel going into the car engine. If the wrong quantity enters, it spells trouble for the vehicle. To ensure only accurate operations, manufacturers use actuators to handle the throttle valve.

The actuator generates motion to open and close the valve at the right pace. That way, only the exact amount of fuel and air the car needs goes in. These types of actuators usually feature a sensor linked to a control unit.

Hence, they work with automation and are not based on user input. Also, they welcome signals from other sensors and switches in the car. The actuator will know the perfect position to place the throttle via these signals.

Air Flap Management

Actuators also help with the engine intake and exhaust systems. In particular, we’re talking about the air flaps controlling airflow into the systems. How the flaps work is simple. They open to allow air to come in and close when there’s enough inflow. An actuator facilitates this open-close movement.

Thanks to their precise motion, actuators ensure the engine isn’t overworked. Excess air inflow can impact the engine. Not to mention the amounts of unhealthy gas the atmosphere will receive if the exhaust isn’t working well. By extension, actuators help reduce emissions by managing the air flaps. They also ensure less noise and generally improve engine performance.

Camshaft Adjustment

If a car’s camshaft is not in good condition, the engine suffers. The component works with the crankshaft, the backbone of any internal combustion engine.

By design, it’s critical for the camshaft to settle in the correct position based on that of the crankshaft. Such precise positioning is best handled by an actuator, which manufacturers use.

In particular, actuators control the valve timing of camshafts in car engines. They vary the timing, depending on the engine’s state at any given time. Also, actuators handle valve overlap, and all these help promote better performance.

Exhaust Gas Recirculation

We’ve already discussed how actuators work in the air flap management of exhaust systems. Another essential function is in exhaust gas recirculation (EGR).

The main advantage of this recirculation is reducing the engine cylinder’s oxygen level. This activity helps lower combustion temperatures and, consequently, nitrogen oxides.

Like most other car engine components, EGR depends on a valve to function. A valve that an actuator operates. Hence, the motion device is directly responsible for the amount of gas that goes back to the engine. Without the actuator, there’ll be serious problems with the EGR system.

Types of Actuators in Car Engines

The end goal of an actuator in car engines is to generate mechanical power. But, as hinted previously, the device gets power from an electric, hydraulic, or pneumatic source. It’s one way you can classify them.

All three types have their best applications. Usually, a manufacturer will use any depending on the car’s requirement. However, electric actuators stand out among others. The reason is logical, as they offer the most benefits.

First, electric power is the easiest to source among all three. It also is the safest. Already, the majority of components in cars depend on electricity. As a result, it’s easy for electric actuators to integrate with sensors, feedback devices, and other systems.

With hydraulic actuators, there’s the disadvantage of having too many parts. These include pumps, filters, valves, and hoses. Each component is essential since the devices deal with pressurized fluid, which also introduces the risk of leakages. Meanwhile, an electric one will only feature a couple wires and harnesses.

The advantage of hydraulic actuators is that they are powerful and can handle demanding tasks. As a result, they’re common in the engine of heavy-duty cars, like trucks, for example.

How about pneumatic actuators? Well, they share a similar disadvantage with hydraulic options in that they feature many parts. However, their main downside is that they’re less powerful. So, in terms of efficiency, they come last.

Nevertheless, car engine manufacturers still use pneumatic actuators in some applications. Since they use pressurized air, they’re helpful if the task demands high speeds and frequencies.

Conclusion

Car engines need to work at the best possible rate. Without them, the vehicle is nothing. But for that to happen, the engine components must operate efficiently, and that’s where actuators come in. The devices will help with any task that requires linear or rotary motion. They come in different types but expect more electric actuators when you check car engines.